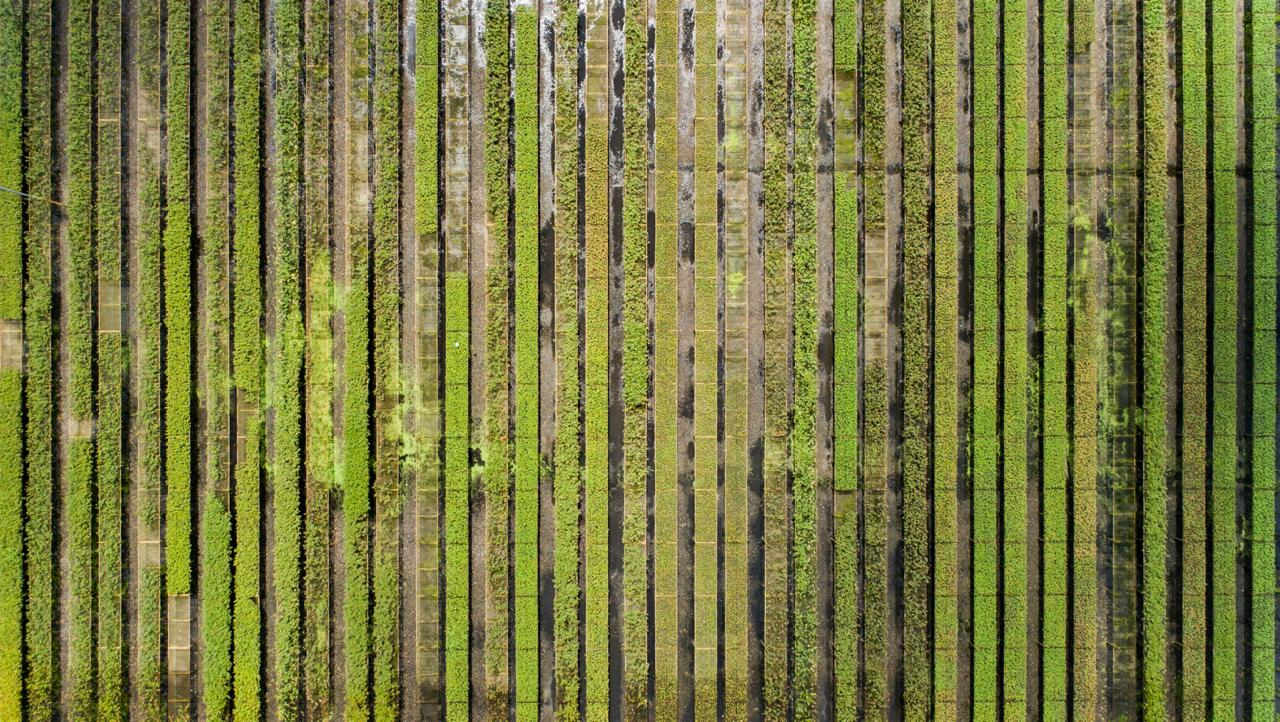

The first is decarbonization, which focuses on reducing GHG gas emissions throughout its operations and value chain. The second lever is to increase carbon removals and storage by conserving native forests and managing eucalyptus plantations sustainably. The third involves expanding the bioeconomy by replacing non-renewable materials with products made from renewable resources like eucalyptus.